Welcome to the Firesparta website.

We hope the pack has delivered you some key information along with a visual understanding of how best to take care of your stove and flue.

Enjoy getting the most from the 3 elements. If we source the best fuel, understand and control the air flow and keep the heat optimal and consistent, the stove can last a lifetime with little maintenance.

Keep in mind that every stove and chimney will perform differently on any given day, so you will have to tinker to get the best results.

TOP DOWN FIRELIGHTING

This Method of lighting a stove helps to heat the flue gases quickly, this will warm up the chimney and start a syphon of powerful up-draught. It also removes the need to open the door to re-fuel while the fire is still at a relatively low temperature, which will likely pull back some smoke into the room!

Modern stoves have big glass doors with reduced size outlets, they are designed to be economical and keep the heat down, pushing unburnt particles back down into the fire. This is the reason why this method of lighting your stove is recommended.

To make lighting your stove as easy as it can be, its a good idea to set aside some of your best split logs, cut to fit your stove perfectly and kept warm inside… (cold wood is hard to light).

Its recommended to start with smaller logs no larger than 3-4″ in radius, also some good quality kindling and firelighters.

STEP 1

Start by placing two small to mid-sized logs down on the fire bed, spaced apart slightly.

STEP 2

Build your kindling above the logs, criss-cross the kindling in layers, making sure there is space between to allow for the air to pass through. Make sure you have enough kindling and the ratio is around 1/3 logs and 2/3 kindling.

STEP 3

Place your firelighter either between the two bottom logs or somewhere in the middle of the kindling stacks. A good firelighter will burn hot and at a steady rate, helping to ignite the kindling.

STEP 4

Make sure your stove is set to the primary airflow position, or with all of the primary and secondary air vents open together. It may help to start your stove with the door slightly ajar, especially if the chimney is very cold, this pulls warm air into the stove which will help kick start the steady flow of heated air pressure. Now its time to ignite your fire…

STEP 5

Be mindful of what is happening in the chimney, the initial goal is to warm up the flue, and this heat will create a powerful and constant up-draught, but we are working against the colder air and the negative atmospheric pressures which can change on any given day.

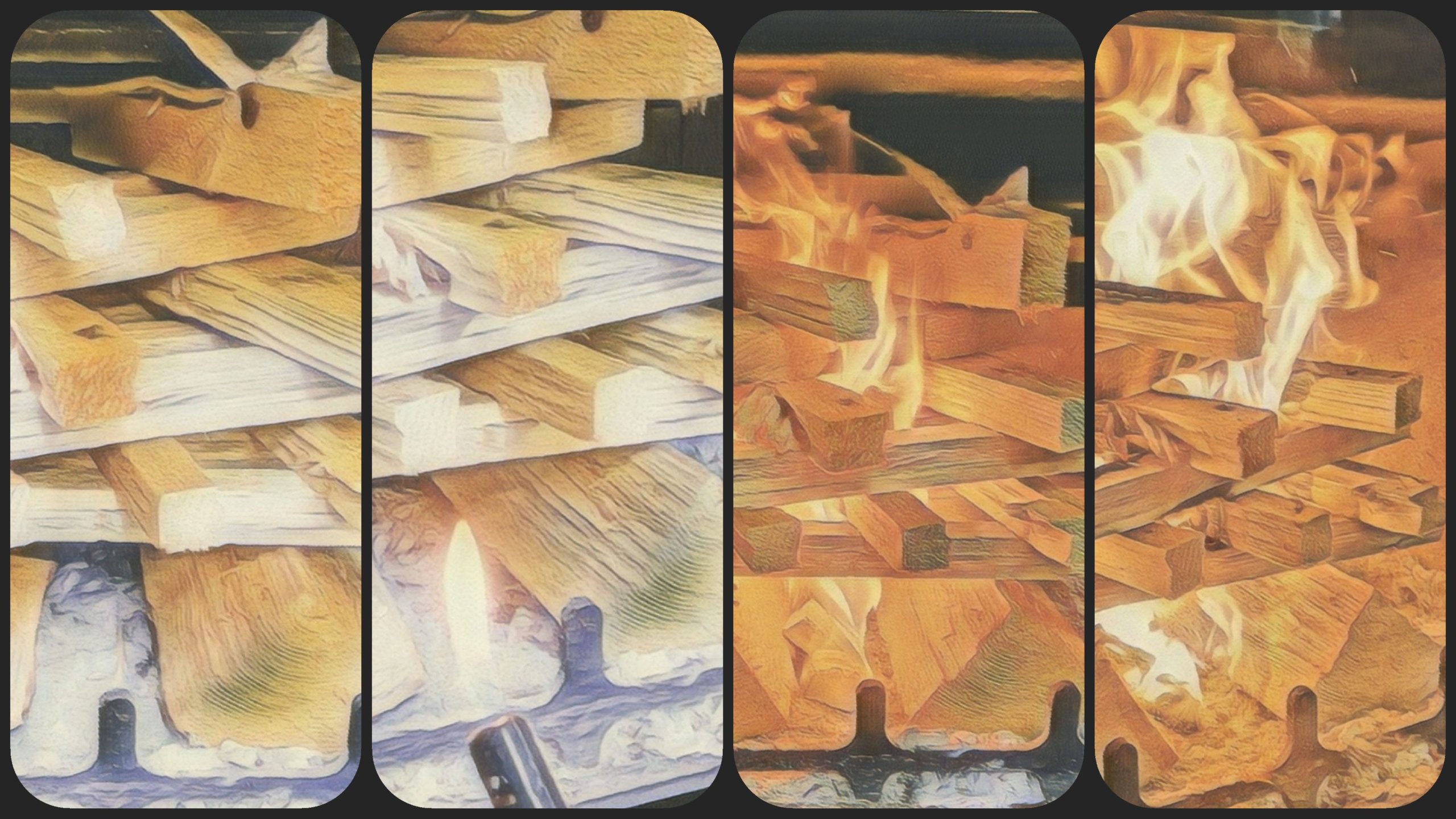

The pictures below show an example of these initial steps;

After around 5-10 mins you will see the flue gas temperature pushing upwards of 200°F, at this stage we may be able to turn our attention away from primary air and focus on the secondary and tertiary air control, but more importantly we must not stifle the fire at this early stage, be patient if its not ready.

Tinker with your air-flows and keep pushing towards the optimal temp range. Once the stacks of kindling have almost burnt away and fell into the logs, its time to reload your stove with 1 or 2 smaller logs**.

**Be careful when opening the door, secondary air is pushing hot air down the front of your stove glass. Open the door slow and gentle so smoke doesn’t puff back, look closely and you should be able to see the pressure change back to primary air**

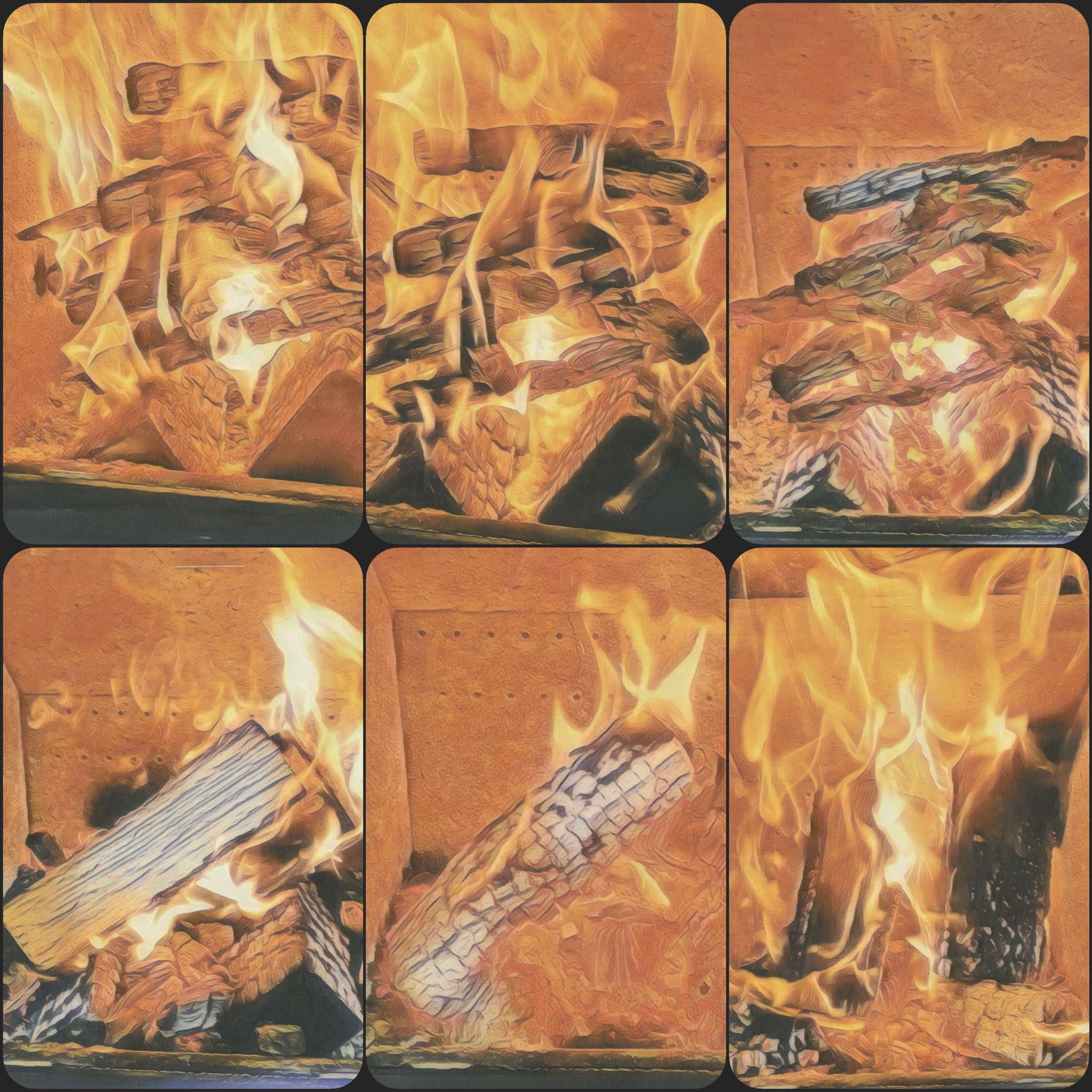

The pictures below show the fire heading towards its optimum temperature with the secondary & tertiary air taking over and being reloaded for the first time;

OXYGEN

Your stove will either have air sliders that are located on the front of the stove, separating the Primary and Secondary air intakes or more modern stoves have a single air control which opens and closes an inlet located on the back of the stove, the control lever is normally located at the bottom of the stove.

The manufacturers handbook will guide you to find the controls and how to set the positions.

Primary air provides the essential oxygen to ignite the fire.

It rises up through the combustion chamber, breaks down the fuel into hot gases and heats up the stove to its optimal temperature.

Once the stove reaches its optimal temperature, moderating this airflow will retain the heat within the stove, prevent heat loss up the chimney and allow the secondary and tertiary airflows to take over and operate at their peak efficiency.

Secondary air introduces oxygen at a higher temperature to ensure that the primary gases & particulates are fully combusted.

The gases are re-circulated & re-burned, ‘polishing’ the burn & improving the heat extraction from the fuel.

Hot air sweeps down the glass, keeping it clear of any soot deposits.

Fine-tuning this airflow is key to unlocking the stoves peak performance & efficiency.

Tertiary air injects a boost of oxygen directly into the fire, this ignites any remaining hydrocarbons and volatile gases, ensuring that very few emissions escape.

This airflow will be pulled in automatically when the stove reaches its optimal temperature.

Working in tandem with the secondary airflow to achieve a clean, bright and complete combustion of solid fuel.

CARE & PROTECT

Use the magnetic stove pipe thermometer included and keep your stove operating in the optimum heat range.

control output

It is essential to recognize that we can control the stove with our fuel supply. One of wood’s greatest qualities is its flexibility in being adjusted to match our energy needs.

A frequent misconception is that heat output can be effectively regulated through oxygen adjustment; however, for optimal performance, stoves should always operate with clean and efficient combustion.

Each stove is assigned a nominal heat output (kWh).

In practice, the output can be varied by adjusting the fuel load and refueling frequency, without negatively affecting combustion quality.

For instance, a stove rated at 5 kWh nominal output will generally provide a heat output range of approximately 2.5 – 7.5 kWh.

The calorific value of wood is defined by its dry weight, and our goal is to release this stored energy as efficiently as possible.

Splitting up the calorific value correctly is what allows for a clean, efficient burn.

Several factors can influence energy efficiency, but correct operation of the stove is key. We can either extract the energy from solid fuel into light and heat, or waste it, by turning that energy into smoke and soot!

DESIGN & FUNCTION

Wood burners have a solid base and require good airflow from above the fuel.

No airflow is needed to push through wood and burning on a bed of ash will improve the combustion efficiency

Use well-seasoned or kiln-dried wood with a moisture content of ≤20%.

Hardwood is dense and consistent, while softwood burns faster and hotter. The calorific value of wood is determined by its dry weight.

Wood preparation is key. Ensure the wood is well-split and sized correctly for your stove. Always have some warm, dry wood set aside for easy lighting.

Both wood and multifuel stoves can burn sustainable, eco-friendly briquettes, which offer a high calorific value and low moisture content. Just remember to avoid overburning!

Multifuel stoves have a raised grate, enabling airflow circulation beneath the fuel bed, pushing air up through the fuel while allowing excess ash to fall away.

‘Smokeless’ fuel is designed to break apart as it burns, minimising smoke. All fuels need the right airflow for a clean and efficient burn – avoid slumbering at all costs!

MF grates vary!

Partially open or ‘hybrid’ grates are not designed for full loads of compressed multifuels. When burning wood only, close the grate and allow the ash to build up.

Avoid burning wood and coal together, this will cause corrosion in both the stove and flue. The moisture in wood combines with the sulphurs in the coal to form sulphuric acid.

Jargon

‘AIR WASH’ – This is a feature of most modern stoves. Air is deflected and flows down the inside of the glass to help prevent soot sticking on the glass.

BAFFLE PLATE – plates that sit in the top of the firebox. Its purpose is to help keep heat in the firebox, and not lost up the chimney. Combustion gases and smoke must flow around the plate before exiting the stove, this slows down the flue gases, resulting in improved efficiency and cleaner burning. All modern stoves will have some sort of baffle plate or multiple plates.

‘CLEANBURN’ – A system used in modern stoves in order to obtain higher efficiency from the burn, additional air is introduced to the stove to make sure most heavy particles can be combusted and volatile gases don’t disappear up the flue providing a complete burn.

ClearSkies – The ClearSkies Scheme certifies solid fuel local space heaters and solid fuel local space heater boilers that meet net efficiency and carbon monoxide (CO), nitrogen oxides (NOx), organic gaseous compounds (OGC) and particulate matter (PM) emissions criteria. Independent test results of a product from an approved laboratory allows its producer to apply for a ClearSkies Mark licence to use the ClearSkies Mark on the certified appliance.

CC / Closed Combustion – If your stove is labelled with CC or closed combustion, this means the stove is able to take direct air into the stove via a closed combustion ducting kit or CCDK. This allows the air to flow directly from outside the house into the stove.

CE mark – A European standard by which products are rated.

Collar / Outlet / Spigot – a steel or cast-iron ring that bolts to the top or rear outlet of a stove, into which sits the first section of flue pipe. On stoves with both top and rear outlets the outlet not in use is sealed with a Blanking Plate.

CONSUMABLES – many of the components inside the firebox that make up the stove, the ropes, seals, firebricks, ash pan & grate, these items are classed as consumables and will have a certain lifespan dependent on the amount of use they get, and the temperatures involved but they are designed to be easily replaceable. Manufacturers will generally exclude all these items from any guarantee or warranty as they have no control over how a customer uses the stove.

DEFRA (Defra approved / Defra exempt) – this is a term often mentioned in relation to stoves. The Department for Environment, Food & Rural Affairs is responsible for, among other things, environmental protection, and control. This includes ensuring compliance of the Clean Air Act – a law that prohibits emissions of smoke within smoke control areas.

Eco-Design 2022 – Ecodesign is the European Union’s programme for lowering emissions across Europe. Ecodesign was implemented on 1st January 2022 for wood burning and multi fuel stoves. The regulations cover a broad range of emissions: Particulate Matter (PM10 & PM2.5), CO2, NOx, OGC (organic gaseous compounds) and CO. Ecodesign Ready stoves can reduce particulate emissions by 90% compared to an open fire and 80% compared to an old stove.

FIRE BRICKS – In most stoves the inside walls of the firebox are lined with loose-fitting panels called firebricks. These help to keep heat in the firebox, leading to higher efficiencies and cleaner combustion. Traditionally the firebricks were made from Refractory Clay, but now many stoves are lined with Vermiculite boards instead. Some older stoves are lined with cast iron inner plates.

HETAS – HETAS is the official body recognised by the Government to approve biomass and solid fuel heating appliances, fuels, and services, including the registration of competent installers and servicing businesses.

KW – The standard unit for the measurement of power is the watt. KW means 1000 watts. Commonly used to measure the power output of heaters. A small wood-burning stove may have a nominal output of 5KW but behind that will be a range of output. The actual output you get in use will depend on the amount and quality of fuel you are burning.

EXTERNAL RIDDLER – Some Multifuel stoves have a Riddling Mechanism or ‘Riddler’ – part of the grate rotates or shakes to allow the ash to fall through the grate into the ash pan below. The riddler is usually operated by a knob on the front or side of the stove which is pulled/pushed. This was really designed for Coal burning stoves. ‘Smokeless fuel’ is fuel that does not need to be riddled and will break apart unaided to allow air to pass through and not suffocate the fire.

SEASONED WOOD – To burn wood efficiently, wood needs to be well-seasoned with a moisture content of below 20%. You can buy ‘READY TO BURN’ wood locally. Once chopped, wood need to be stored for at least a year in a dry shelter with good air circulation. Burning unseasoned wood can seriously damage your stove and flue. You can check that your wood logs are sufficiently dry with an electronic moisture meter. Ideal types of wood to burn include:

Ash

Beech

Birch

Elm

Hawthorn

Hazel

Oak

SIA – The Stove Industry Alliance (SIA) was formed in 2008 to promote the benefits of wood-burning stoves and biomass appliances. The SIA is an association of stove manufacturers, distributors and wood fuel suppliers.

Smoke Control Zone / Smoke Exempt (SE) – A designated geographical area inside which the burning of unauthorised fuels is not permitted in a house unless in an SE (smoke exempt appliance). Most large cities will be Smoke Control Zones.

VITREOUS ENAMEL – Refers to the most common type of pipe used to connect the stove to the chimney